ESD Control Materials and Electrical Safety Hazards

For many years companies, that handle electrostatic discharge (ESD) sensitive products, have asked if it is safe to connect their employees to ground when they are working with powered equipment.

The answer to this question is not a simple “yes” or “no”. The grounding methods required by ESD Control Programs such as ANSI/ESD S20.20 and IEC 61340-5-1 often conflict with the requirements for protecting personnel from hazardous electrical currents in some operations.

The intent of this white paper is to call attention to the items that should be considered when reviewing operations, where ESD sensitive devices are handled, from a personnel safety point of view. This paper will also demonstrate why it is not recommended to make electrical safety decisions based solely on current limited DC voltage resistance measurements.

White paper contents:

- Background Information

- What constitutes an electrical shock hazard

- Sources of electrical safety shock hazards

- Semiconductor ESD sensitivity trends

- ESD Program trends related to personnel

- Personnel electrical safety and the use of ESD control materials

Background information – Electrical Shock Hazards

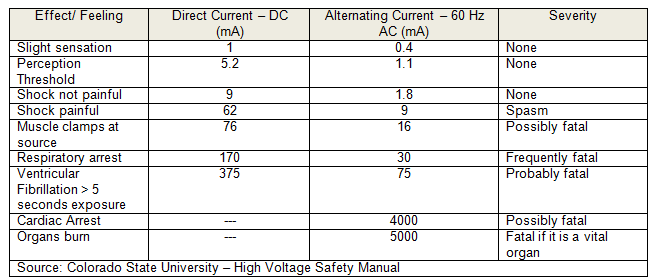

First, let’s look at what is generally considered to represent an electrical safety shock hazard to people. The following table lists the effects of DC and AC current on the human body.

Table 1: Effects of Electric Current on the Human Body

It is a well known fact that electrical current (either DC or AC) can be harmful to personnel under the right conditions. In order for a person to receive an electrical shock two things must happen:

- There must be an exposed electrical source that a person can contact

- After contact with a live power source there must be a path to ground that includes the person’s body.

Let’s address point “1” first. Commercial equipment such as computers, telecommunications equipment, televisions, stereo equipment, computer gaming consoles etc. are all manufactured to various safety standards depending on where the products are built and where they are ultimately sold. These standards (such as UL/IEC 60950) address the requirements for ensuring the safety of electrical products.

In the United States, nationally recognized testing laboratories are responsible for the testing of electrical products. Electrical products that have been tested are typically marked with the testing agency’s label or other identification to signify that the product has successfully passed testing.

Products that have recognized testing lab approvals, such as Underwriters Laboratories (UL), should not be considered as a source of shock hazards to personnel under normal use conditions. This applies to commercially available electrical equipment found in call centers, offices, computer rooms, in homes and on manufacturing production lines, provided the products are being used as designed. It is safe to ground people who use this type of equipment.

There are situations where personnel are expected to be exposed to live electrical voltages such as:

• Electricians working on powered circuits

• Technical service personnel working on powered customer equipment

• Manufacturing personnel working on products with exposed power or performing functional tests or hi-pot testing

In these situations, workers may come into contact with hazardous voltage sources. It is generally accepted that personnel in these situations should be isolated from ground. If while in contact with a hazardous voltage source the person also comes into contact with ground the person could be exposed to a potentially lethal shock. Contact with ground can happen if the person were to accidentally touch the grounded metal frame of the equipment being worked on, the grounded chassis of adjacent equipment, grounded metal conveyors or any metal pipe or part of the building that is connected to ground. In addition they could, as part of the company’s ESD control program, be connected to ground via various ESD control items such as a grounded wrist strap system or through ESD footwear while standing on a grounded ESD floor.

Most companies, that have operations where personnel are exposed to hazardous electrical voltages, have mandatory training programs for personnel that identify the risks and incorporate, where possible, protection systems that limit or reduce the opportunity of shock hazards. The implementation of this type of safety program allows the users of ESD flooring systems to select a static control floor that is right for the application thus permitting the use of any properly qualified flooring system (conductive or dissipative) while eliminating possible safety hazards.

Background – Electronic Device – ESD Sensitivity Trends

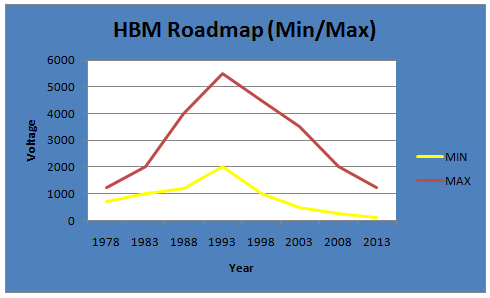

Semiconductor devices have been becoming more and more sensitive to ESD since the mid-1990’s for a variety of reasons. The ESD Association has published a Technology Roadmap for semiconductors that addresses this trend. The Roadmap contains trends for Human Body Model (HBM) and Charged Device Model (CDM) sensitivities. The following graph shows a modified version of the HBM Roadmap that also includes the ESD trends for Radio Frequency (RF) devices. The general trend shows that semiconductor devices are becoming more sensitive to ESD over time.

The two lines in Graph #1 define the maximum and minimum HBM voltage thresholds for the vast majority of semiconductor devices. When designing ESD control programs the minimum values are the most important. Graph #1 shows that by 2013 some semiconductor devices will have HBM ESD sensitivities in the 100 volt range.

Graph #1 – HBM Roadmap including RF Devices

Background – ESD Control Programs

Many companies that manufacture or handle unprotected electronic products have implemented control programs to prevent ESD.

One of the goals of ESD Control Programs, like ANSI/ESD S20.20, is to connect all conductors to ground. “Conductors” include the ESD sensitive devices themselves, work surfaces, mobile carts, packaging, flooring and personnel. When all conducting items are connected to ground each item is brought to earth or a near zero potential. When each item is at the same potential ESD events will not occur during contact with each other and the products will not be damaged.

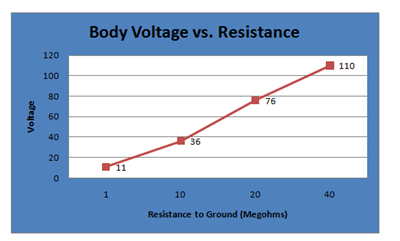

The semiconductor ESD sensitivity trends have resulted in the development of ESD program standards such as ANSI/ESD S20.20 and IEC 61340-5-1. These standards have set an upper limit of 3.5×107 ohms for the resistance to ground of personnel. Graph #2 shows the voltage generated on a person’s body versus the person’s resistance to ground. The graph clearly shows that the lower the resistance to ground value the lower the voltage on a person’s body. This is an important consideration for those who design ESD control programs and is part of the reason that the user community has been moving towards more conductive footwear/flooring systems since the mid 1990’s.

Graph #2 – Body Voltage Generation versus Resistance to Ground

From a semiconductor protection point of view the lower resistance values for footwear/flooring systems is desired and in some cases even necessary. However, the lower footwear/flooring resistance values have raised concerns about the electrical safety of these systems. Some suppliers of ESD flooring insist that only dissipative flooring (resistance to ground of between 1.0×106 and 1.0×109 ohms) can provide protection against electric shock hazards. Their suggestion that dissipative flooring is inherently safer than conductive flooring is not necessarily true.

Personnel Safety and the use of ESD Control Materials

It would seem that the requirements for protecting personnel from electrical shock hazards conflict with the grounding requirements of established ESD control programs. How do companies address this issue?

Many companies use Ohm’s Law to calculate the electrical current which might pass through various ESD control items that contact hazardous voltage sources. Ohm’s Law can be stated as a mathematical equation, I=V/R, where I is current in amps, V is voltage and R is resistance in ohms. If you know any two of the values you can calculate the third.

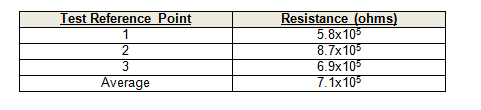

Let’s look at an example of how this might be applied to a footwear/flooring system. The resistance of a person wearing ESD footwear, while standing on an ESD floor, can be tested using a standard test method published by the ESD Association. ANSI/ESD STM97.1, (Floor Materials and Footwear – Resistance Measurement in Combination with a Person) specifies the system testing of footwear/flooring products used with ESD sensitive devices.

The following is an excerpt from a footwear/flooring test report. The resistance values are measured from a probe held in the test subject’s hand, through the ESD footwear and ESD flooring to the floor’s groundable point.

Table #2 – System Resistance to Groundable Point

The test voltage used for this test was 10 volts as allowed by the procedure. Taking the lowest system resistance value (results in worst case current) we can calculate the current (I) during the measurement using Ohm’s Law (I=V/R).

10 (volts) / 5.8×105 (ohms) = 0.017 milliamps

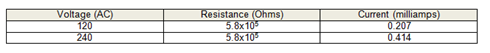

The next step is to calculate the current using the hazardous voltage sources that might exist in a process. Let’s assume that personnel are exposed to 120 and 240 volts AC. Table #3 shows the “calculated” current for these higher voltage values. Note: It is assumed for this example that the resistance value does not change.

Table #3 – Calculated current based on system resistance

Based on the results from Table #3, some companies would assume that the resistance of the ESD floor and footwear, at worst case, will limit the current, passing through a person to values of less than 5 milliamps for AC voltages up to 240 volts. Based on Table #1, this footwear/flooring combination would be considered to be safe for use with personnel that are exposed to AC voltages up to 240 volts.

The Reality

There are problems with the assumptions made above as follows:

1. The test standards do not replicate installed conditions, especially for flooring and footwear systems. The presence of moisture in the process (as well as other installation issues) can change the resistance readings, in some cases by several orders of magnitude.

2. The current calculations in Table #3 were made with the assumption that the resistance values from Table #2 will remain constant at all applied voltages. In reality, the resistance of most materials will change depending on the voltage source, current applied and the measurement electrification time.

Let’s look at each of the above points more closely specifically as they relate to ESD footwear.

The in-use conditions for ESD footwear and ESD Flooring are often different then those found in qualification testing. Some of the items that might differ are:

- Relative humidity (RH) – the actual values can be much higher than the 12% and 50% values required in qualification test depending on the location and environmental conditions at a facility

- The presence of moisture in the building’s foundation can cause the resistance of the flooring to decrease below the values measured during product qualification under controlled conditions

- The resistance of ESD footwear can also change due to moisture. Footwear can become wet due to the presence of conducting liquids found in the manufacturing process. Shoes that are worn outside can also become wet as personnel walk on wet pavement.

Any one or all of the above items can cause a drastic lowering of the system resistance values. A lower resistance to ground value will result in an increase in current if personnel come into contact with an exposed power source.

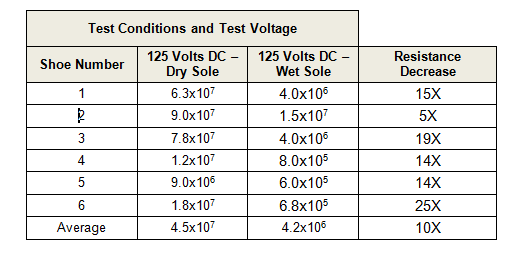

The following data came from an ESD Association Standards Committee study looking into the testing of ESD footwear and the effects of moisture. The following data represents one style of ESD shoe that was tested in the “normal” state (similar to product qualification) as well as after the shoe soles were immersed in water.

Table # 4 – ESD Footwear Testing – Dry versus Wet

As shown in Table #4, the presence of moisture on the soles of these ESD shoes lowered the resistance. In this case, the average reduction in resistance was just over one order of magnitude. The resistance of shoe Sample #6 was more than 25 times lower wet versus dry.

The above data shows that the resistance, for these ESD shoes, can change based on the presence of moisture. These values were obtained using current limited resistance meters that comply with the equipment requirements called out in product qualification standards.

As stated earlier many companies make decisions concerning personnel safety based on the resistance values obtained from supplier specification sheets or through their own product qualification testing of ESD footwear, ESD flooring and other ESD control items. In each case the hazardous current is “calculated” with the assumption that the resistance of the item or system does not change. For most materials this assumption is not correct.

To test this assumption several ESD control items were exposed to higher voltages and currents than are normally found during product qualification tests. The following table shows the results for an ESD shoe, an ESD garment and the conductive scrim of an ESD work surface. For each ESD control item the following readings are displayed:

-

The resistance of the ESD control item using resistance meters that meet the requirements of industry standards.

- The calculated current for that item assuming that the resistance for the ESD control item does not change.

- The actual current flowing through the ESD control item was measured, using a current meter, after exposure to higher DC and AC voltage sources that one might find in the some manufacturing processes. The resistance was then calculated.

Table #5

The data shows that the resistance of an ESD control item could change when exposed to higher voltages. In the case of the ESD mat scrim, the 22 milliamps could represent a possibly fatal situation (based on Table #1) if the person were to touch an exposed 120 volt (AC) power source while in contact with an exposed ESD work surface scrim. When the current is calculated, based on the original test resistance, the conductive scrim would appear to be safe for personnel.

Conclusions

- Commercially available electrical equipment does not pose a threat to the safety of personnel if the product meets the required national testing standards AND the product is being used as intended.

- Decisions related to personnel safety should not be made based on the resistance measurements made using current limited resistance meters.

- No ESD material supplier can guarantee the electrical safety of their products based on the resistance tests specified for ESD control products and materials such as ANSI/ESD S7.1 or ANSI/ESD STM 97.1, regardless of whether the floor is conductive or dissipative.

Recommendation

If your company has operations where personnel are exposed to hazardous voltages a knowledgeable safety authority should review each operation to verify the existence of an electrical hazard and develop procedures to ensure that personnel are truly safe.

In most cases the solution will be to isolate the person from ground or to install other safety devices, special procedures and most of all training to ensure that personnel cannot come into contact with exposed power sources.